Alligator

March 2022

Overview

Overview

During the past 6 decades, production of farmed American alligators (Alligator mississippiensis) for their hides and their meat expanded significantly, even as the industry shifted to fewer and larger operations. Louisiana continues to dominate the industry, but there are some farms in Florida, Georgia and Texas. In 2020 376,578 farmed alligators were harvested in Louisiana, with a farm gate value of $74.5 million, up considerably from $28.7 million in 2010. While the number of U.S. farms selling alligator hides has declined, the number of hides sold each year varies due to global economic conditions and environmental impacts on nesting success (especially flooding from hurricanes and tropical storms). Consolidation within both the international tanning sector and farming operations has been cited as a significant force exerting downward pressure on profitability. The luxury status of alligator hide products makes them particularly susceptible to market volatility when global economic downturns occur.

American alligators have been hunted for millennia in the southeastern region of North America, first by native peoples and subsequently by European settlers. The harvest of alligators has had a commercial component since the late 1800s. As commercial tanning facilities were established in places like New York, the demand for alligator hides increased dramatically. By the 1950s and early 1960s, alligators were widely hunted throughout the southeast with no regulations to manage or protect their populations, which were rapidly overexploited. As a result of serious reductions in breeding alligator populations most harvests were banned by the late 1960s. Under the 1973 Endangered Species Act, the U.S. Fish and Wildlife Service placed alligators under protected status throughout their range.

Once protected, alligator populations recovered rapidly. As a result, many states reopened limited harvesting of alligators and have adopted conservative management of their alligator populations. In Louisiana, the alligator farming industry is widely cited as the primary factor in recovery of alligator populations, because coastal landowners now manage the habitat to maximize the number of alligators nesting on their otherwise unproductive property. This in turn generates income from the collection of alligator eggs for incubation and grow-out on farms.

Sustainable management programs for alligators are in place in Louisiana, Florida, Georgia, Texas and South Carolina. Programs include a combination of farming, ranching and direct cropping of wild alligators. In 1983, the U.S. Fish and Wildlife Service once again changed the classification of the alligator throughout its range under the Convention of International Trade in Endangered Species (CITES) of Wild Fauna and Flora, this time from “threatened” to “threatened for reasons of similarity in appearance” to a number of endangered crocodile and caiman species.

In Louisiana, the density of alligator nests sighted in annual surveys increased more than threefold from the early 1970s to the mid-1990s. By the mid- to late 1980s, alligator farming based on collection and incubation of eggs from the wild reached commercial proportions in both Louisiana and Florida. Alligator farming and the demand for hatchlings has become an important conservation incentive for wetland landowners to maintain their lands as prime alligator habitat, which in turn has benefitted all manner of wildlife.

Production

Alligator farming provides producers an opportunity to generate high-valued products year-round for both national and international markets. Compared to other animal industries, it requires small tracts of land and does not have adverse effects on the environment when facilities are properly designed and operated. It also benefits wetland conservation where state agencies permit alligator growers to stock their farm with hatchlings collected from private wetlands, providing the owners of the wetlands some incentive for maintaining them and ensuring no net loss of animals in the source populations. However, operating an alligator farm is very expensive. Large amounts of capital are required at start-up, and a farmer may have to wait up to three years to start generating income.

When planning the construction of an alligator farm, remote locations are generally preferable. Alligator wastewater has a particularly unpleasant odor, so any nearby neighbors may take exception to (or legal action because of) the smell the farm will generate. Additionally, alligators are easily disturbed. They are frightened by noise from traffic (especially louder vehicles), airplanes, helicopters, garbage collection, agricultural machinery, etc. Constant disturbances will result in reduced growth, increased stress and possibly reduced disease resistance.

Nonetheless, an alligator farm must not be so remote as to complicate regular feed deliveries and access to reliable utility service. A source of abundant clean water will be required, as will a means to heat it for refilling grow-out houses after flushing. The required volume will depend on the number of animals to be produced and the depth of the submerged areas within each grow-out building. Annual supplies of eggs or hatchlings are essential to successful operations, and should be a central component of the business plan for any commercial alligator farm.

From a regulatory standpoint, alligator producers have come under increased scrutiny in recent years as a result of the volume of concentrated effluent they produce on a regular basis. Alligator sheds are typically flushed every other day, and the designation of alligator production as a form of confined animal industry has been debated over the past several years. As pressures mount on all of agriculture to address water use and wastewater issues, alligator producers may be forced to modify current management practices.

Most alligator farms store used water in holding ponds. Depending on the size of the facility and local and state regulations, it may be necessary to aerate waste water using a traditional livestock oxidation pond approach until it can be irrigated onto pastures or cropland. An adequate waste water system will be required by local authorities, so investigate the regulations and permits required to discharge into a public drainage.

The farmed alligator production process begins in the marsh with eggs laid by wild females. A portion of these eggs are allowed to be collected based on nest counts, habitat ratings and population censuses. Regulations vary but are generally very strict concerning where, when and how eggs may be collected. Permits for egg collection are issued with the participation of the landowner. Eggs are then incubated under controlled conditions, and hatchlings are stocked or sold for grow-out. Farmers may establish agreements to collect eggs from private property under the appropriate permits or they may purchase legally taken eggs from collectors.

Growers raise their alligators in heated buildings with both standing water and dry areas, to a length of approximately four feet. The basics to success in raising alligators are 1) keep them warm, 2) keep them clean, 3) keep them calm (alligator producers generally maintain their stocks indoors under low-light conditions) and 4) keep them well fed, but not overfed. All animals must have access to standing water at all times. Hatchlings will accept pelleted diets within a few days after hatching, and remain on a pelleted diet their entire lives. A typical stocking density regime is 1 square foot per animal until a length of 2 feet, then 3 square feet per animal until a length of 4 feet (at which point harvesting often takes place), and 6 square feet per animal up to 6 feet in length. Juvenile alligators have a tendency to pile up when frightened, occasionally resulting in injury or suffocation, so proper densities should be observed and disturbance should always be minimized.

Dietary protein levels are an important consideration, both in terms of cost and water quality. Poor water quality, especially high ammonia and BOD levels, impacts hide quality so feeds and feeding practices can impact hide quality indirectly in rearing environments. Overfeeding, unnecessarily high protein levels, and poor feed conversion rates can all result in excessive ammonia levels in grow-out houses, both in the water and the air. Ammonia appears to have additional detrimental health effects through respiratory impacts at the air/water interface. Since cool-season heating costs can be substantial for indoor grow-out and cleaning activities can stress juveniles, many producers are reluctant to exchange more water than absolutely necessary. This further reinforces the importance of efficient diet formulation and utilization to minimize ammonia excretion and waste production.

Like other livestock and aquatic animals, alligators can sometimes suffer from diseases. A number of viral and bacterial pathogens have been reported from farmed alligators. Alligators have been shown to be particularly susceptible to West Nile virus. And while the virus may not cause significant mortality in many cases, it can have detrimental impacts on hide quality. Exposure to this virus has been strongly associated with subsequent Lymphohistiocytic Proliferative Syndrome (LPS) in alligators. LPS causes skin blemishes, observable as small (1-2 mm) gray spots, especially on the underbelly, and also affects other tissues. These blemishes can greatly reduce the value of the skin, and alligator farmers go to great lengths to keep mosquitoes, the main vector for West Nile virus, out of their grow-out facilities.

It normally takes roughly 15 months for alligators to reach minimum marketable sizes. Once alligators are marketable, they are slaughtered and skinned, but in some cases (such as in Louisiana), not before a pre-designated percentage have been returned to natural habitats to replace the eggs that would have hatched in the wild and survived up to that point in time. Hides are prepared for sale and transport by scraping, cleaning and salting. Meat is butchered and packaged under sanitary conditions typical of any meat-packing operation.

Upon slaughter, a tag is attached to the hide. It will accompany it throughout marketing and tanning until the hide becomes finished leather products. A similar tagging system is used for alligator meat products. At this point in the supply chain, meat can be considered a product, but hides are still more of a commodity.

Marketing Considerations

Historically, hides have been sold for further processing through a variety of channels. Salted skins are measured and graded by size and quality, and then offered for sale. In the past this was done through open auctions, private auctions or direct private sales. Currently, hides are purchased directly by representatives from domestic and foreign tanneries who inspect, grade and quote a price on-site at the farm. Some buyers function as brokers for eventual resale, often on a speculative basis. Domestically, one alligator tannery operates in the state of Louisiana, and three other U.S. tanneries, in Florida, Georgia and New York have also processed skins. Statistics are difficult to compile but in 2014 there were 37 alligator farms reported in four states (Louisiana, Florida, Georgia, and Texas).

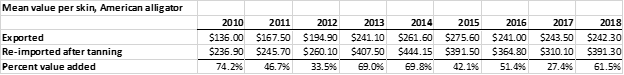

Trends in numbers of operations illustrate the shifting of production to fewer, larger farms, and a competitive marketplace has put downward pressure on profits at the farm level. This pattern has persisted as consolidation progresses in production, tanning and manufacturing. Most profitability occurs in the value-added sectors of the supply chain, as illustrated by hide prices when exported from the U.S. and once they are re-imported as finished skins.

Alligator meat is an important secondary product for farmers, and the principal product for wild harvesters. The wholesale value of processed alligator meat in Louisiana has increased from roughly $3.50 per pound in the 1980’s to $7.00 in recent years. Alligator meat is a healthy choice, low in fat and high in protein. A 4-ounce serving (110 grams) of raw alligator meat contains 24 g of protein, only 2 g of fat, 55 mg of sodium and 55 mg of cholesterol, and provides 110 calories. Industry organizations are taking measures to educate consumers and restaurants with respect to the qualities of alligator meat. Moreover, growers and processors are producing value-added alligator meat products such as sausage and ground patties.

International vs Domestic Demand

Usage of farmed alligators increased steadily for several decades, although variability occurs from year to year as a result of market forces, natural phenomena impacting hatchling availability, and general economic and fashion trends.

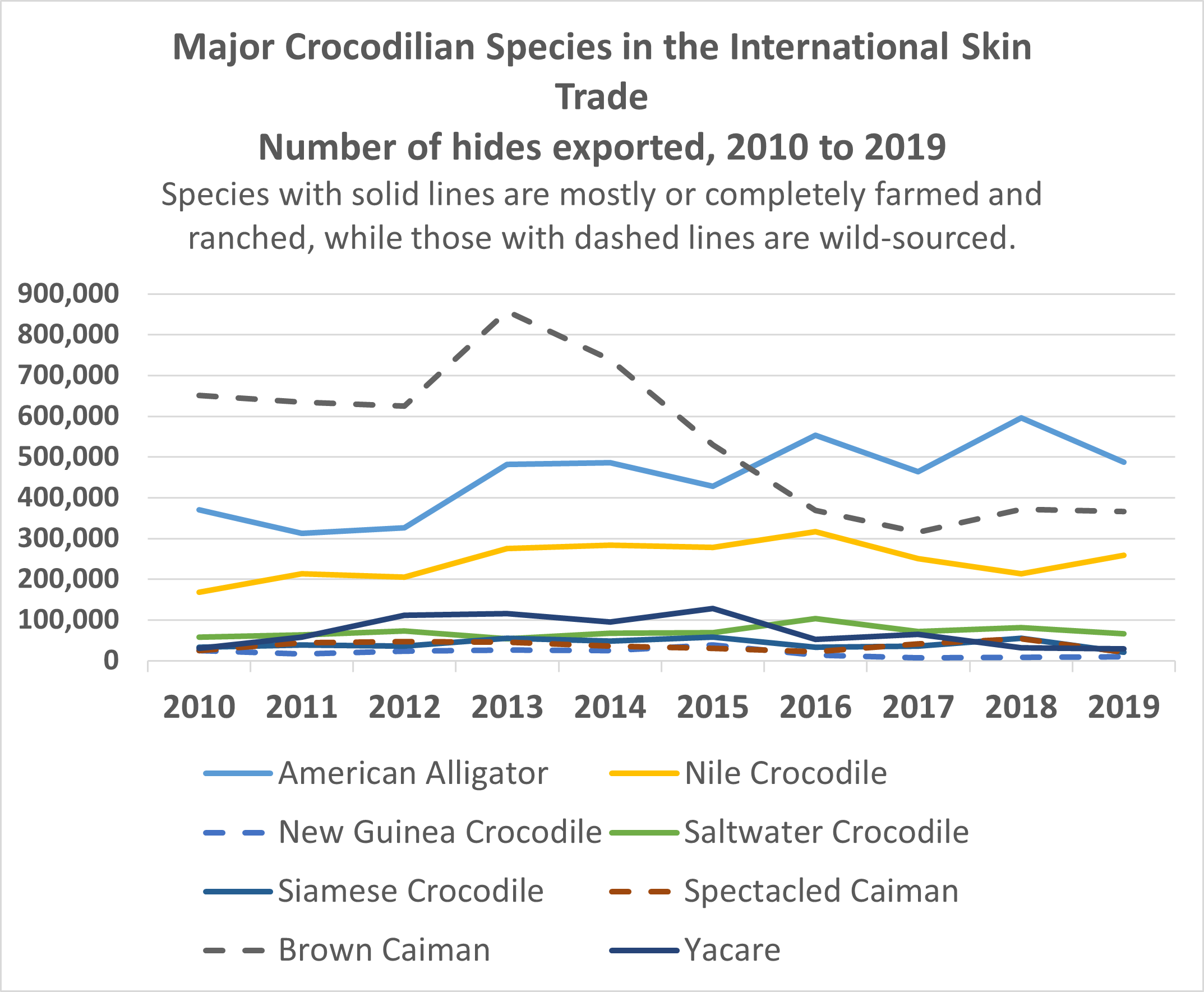

Global trade in crocodilian hides peaked around 2013, at a reported level of some 1.9 million skins. In the following years, annual numbers of hides fell to between 1.0 and 1.5 million. Alligator hides compromised a large portion of the international crocodilian market, and demand for alligator hides and meat is well established in North America, Europe and Asia. All parts of farmed alligators are used for various markets, but skins have historically accounted for approximately two thirds of the total wholesale value.

Alligator skins are used to create a variety of luxury products that range from fashion accessories to upholstery. Ongoing efforts to portray alligator leather products as a positive component of sustainable use and protection of the species appear to have had some impact on consumers’ attitudes, but misinformation still exists, hindering both market access and the conservation benefits associated with alligator farming. There is actually a set of best practices standards as well as a certification program in place to promote responsible husbandry and stewardship of crocodilians. Both are overseen by the International Crocodilian Farmers Association (ICFA) , a professional organization of larger, progressive farming operations.

Although farmed alligators no longer compete directly with wild alligators in the marketplace, other crocodilians from Latin America, Africa, Australia and Asia are direct competitors in global trade. Costs of production for farmed crocodilians from Latin America, Africa and Asia may be somewhat lower than those for U.S.-produced

alligators, and this competitive disadvantage is not anticipated to ease anytime soon. However, quality considerations still provide a sizable demand and global market share for American alligators.

Perhaps the largest barrier to entry in alligator farming in the U.S. involves the initial grow-out cycle and associated cash flow requirements. The need to heat make-up water to the appropriate temperature (89 F) after flushing alligator houses comprises a large part of operating costs. Additional barriers to entry are numerous. They involve reliable, consistent sourcing of hatchlings and feed supplies, locating legitimate buyers and offering sufficient volume to attract their attention, arranging for slaughter and processing of meat and hides in compliance with license and permit requirements, and other regulatory requirements (for example, wildlife, zoning, effluents, health licensing, etc.). Economies of scale also come into play, with some industry observers maintaining that very small and very large operations appear to have competitive advantages.

As mentioned above, alligator farming is associated with numerous regulatory oversight programs. All alligator farmers and trappers must possess the appropriate state and local licenses, and all skins must be tagged with serial numbered tags. International trade of alligator skins requires approval and documentation through the CITES Treaty of Wild Fauna and Flora.

Profitability is determined on a farm-by-farm basis from year to year, reflecting production costs and skin quality. The industry has occasionally suffered temporary reductions in volume because of shortages of eggs and hatchlings resulting from untimely storm damage to nesting habitats. The effects of limited egg collection usually become apparent in the following year, and depending on the financial structure of an operation, high prices for eggs or hatchlings can reduce or altogether eliminate profits.

In each segment of the supply chain, from hatchling suppliers to tanners, there are both large and small operations. The size of operating farms varies, but there has been a long-term trend toward fewer, larger operations. From a producer’s standpoint, the alligator farming industry has already evolved to a commodity product market. Although price competition may become a major determinant of market share under certain conditions, prices offered to producers generally reflect international market conditions.

Resources

- Louisiana Alligator Regulations, April 2021. https://www.wlf.louisiana.gov/assets/Resources/Publications/Regulations/2021_Alligator_Regulations.pdf Louisiana Department of Wildlife and Fisheries.

- Alligator Aquaculture: Rules and Regulations. https://www.fdacs.gov/content/download/64593/file/Alligators-Aquaculture-in-Florida-Rules-and-Regulations.pdf Florida Department of Agriculture and Consumer Services

- Alligator Farming in Texas. https://tpwd.texas.gov/publications/pwdpubs/media/pwd_bk_w7000_1433_alligator_farming_in_texas.pdf Texas Parks and Wildlife.

- Commercial Alligator Farming in Georgia http://rules.sos.ga.gov/gac/391-4-11 State of Georgia, Secretary of State.

- Alligator diet protein content evaluation. https://www.lsuagcenter.com/~/media/system/0/2/7/8/027821bf1dc7e07cc19fc7f28081a72d/lsuagc_summer2013.pdf Louisiana State University Agricultural Center.

- Alligator Production. https://srac.tamu.edu/categories/view/8 Southern Regional Aquaculture Center.

- International Crocodilian Farmers Association. https://www.internationalcrocodilian.com

- International Union for the Conservation of Nature Red List. https://www.iucnredlist.org/search?taxonomies=101018&searchType=species

- World Trade in Crocodilian Skins 2017-2019. https://www.unep-wcmc.org/system/dataset_file_fields/files/000/000/603/original/IACTS_World_trade_in_crocodilian_skins_2017-2019.pdf?1633696185 J. Caldwell, United Nations Environment Programme – World Conservation Monitoring Center. Cambridge.

Prepared by C. Greg Lutz, Louisiana State University Agricultural Center